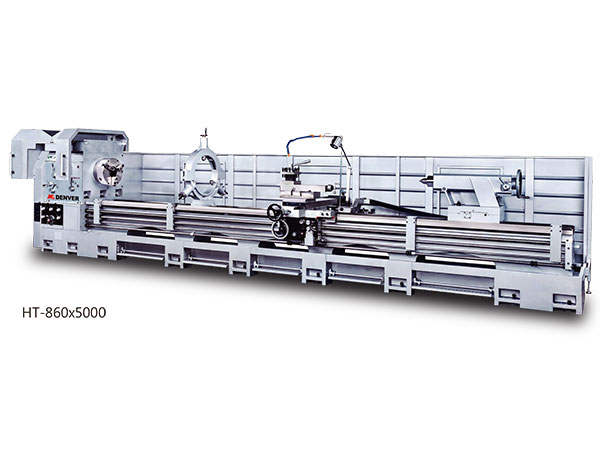

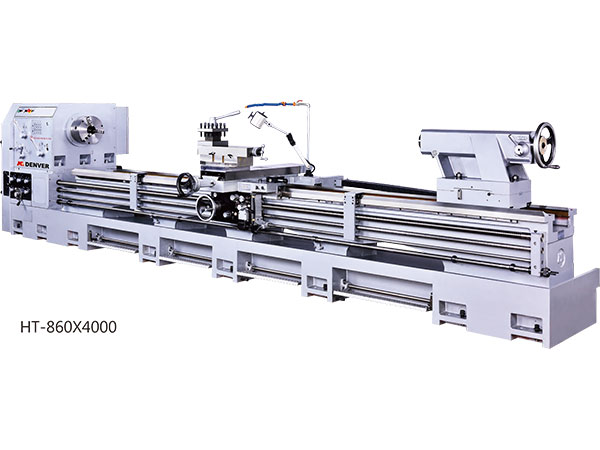

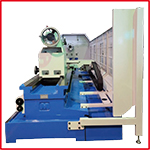

Heavy Duty Lathe

HT-860, 960, 1120, 1220 X 1000, 1500, 2000, 3000, 4000, 5000, 6000, 7000

SPINDLE BORE: 4", 6"

BED WIDTH: 20" (510mm)

*Standard accessories shall be subject to the quotation.

It is suitable for turning and cutting of large work piece and steel rod materials for heavy industries like oil pipe network, aerospace and heavy-duty shaft processing.

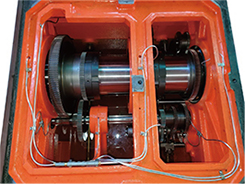

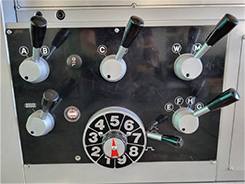

- 1. SPINDLE & HEADSTOCK

- (1) Spindle bore 105mm (4”) or 152mm (6 “), 12-step speed change, turbine speed change mechanism with no easy speed jumping and three point support for the box.

- (2) Spindle bore 6” or more are fitted with adjustable, electromagnetic brake for easy braking adjustment according to different work piece materials and speed.

- (3) Gear and shaft are made of super alloy material with NSK bearings to offer durable cutting and low production noise.

- (4) Sealed oil bath lubrication system with enforced oil supply by mechanical pump to achieve better lubrication effects.

- (5) Photo shown headstock with spindle bore 152mm (6")/speed 12 steps.

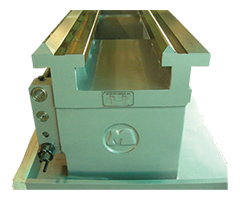

- 2. BASE

- (1) The structure of bed is adopted high toughness Meehanite cast iron; stabilize properly parallel precision. Bed ways are induction hardened and ground.

- (2) One -piece casting base for processing capacity to be more stable.

- 3. Gear Box

- Adopt quick-change universal metric/inch gearbox for inch,metric, DP, MP, threading and multiple threads, all function is reached without any change gear, wide and complete range of threads and operating easily to improve production efficiency.

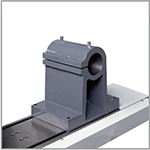

- 4. Tailstock

- Two stage feeding device, installed with saddle- tailstock device for tailstock body easy moved smoothly and labor saving operation

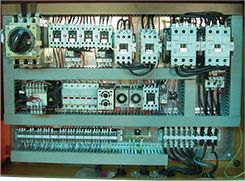

- 5. Electric component

- 20HP motor, 2 stage safety startup device and overloading power cut system.

- 6. Apron

- Equipped with rapid feeding device, forward and reverse movement, and a safety device, with automatic sealing oil bath lubrication and cross rapid feeding.

- 7. Saddle

- Anti-friction processed surface with regular oilinjection, lubricated and friction endurable

- 8. Casting

- The main material of main structures like base, spindle, saddle and tailstock are all made of FC-30 steel, which are annealed, not deformed.

- 9. Processing

- Base, spindle, saddle, dovetail slot surface of cross slide, top slide and tailstock quill are high frequency

- 1. CE equipment

- 1-1. CE electricity

- 1-2. Chuck guard

- 1-3. Toolpost guard

- 1-4. Leadscrew cover

- 1-5. Back splash guard

- 2. Follow rest

- 3. 4-jaw independent chuck

- 4. 3-jaw strong scroll chuck

- 5. Steady rest ø16", ø20"

- 6. Halogen light

- 7. Digital readout

- 8. Taper turning attachment

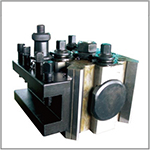

- 9. Quick change tool post European quick change toolpost (instead of 4-way tool post )

- 10. Grinder

- 11. Boring attachment

- 12. Double chuck

- 13. Rear chuck guard

|

|

|

| 1-1. CE equipment | 1-5. Back splash guard | 2. Follow rest |

|

|

|

| 3. 4-jaw independent chuck | 4. 3-jaw strong scroll chuck | 5. Steady rest ø16", ø20" |

|

|

|

| 8. Taper turning attachment | 9. Quick change tool post | |

|

|

|

| 10. Grinder | 11. Boring attachment | 12. Double chuck |

- 1. XZ-axis auto. lubrication system

- 2. Metric / Inch gear box

- 3. Longitudinal and cross rapid feeding

- 4. Coolant device

- 5. Longitudinal adjustable position feed stop

- 6. Tailstock two steps device -taper MT#6

- 7. 3-jaw scroll chuck SC-12"

- 8. Back plate of chuck

- 9. Steady rest 11.5”

- 10. Center sleeve MT#6

- 11. Dead center 2 pcs

- 12. Toolpost screw wrench

- 13. Level pads

- 14. Tools & tool box

- 15. Operation manual

- PS. Electromagnetic brake for spindle bore 6", 9", 10", 12"

Unit: mm

| ITEM | HT-860 | HT-960 | ||||

|---|---|---|---|---|---|---|

| MODEL | 1000 | 1500 | 2000 | 3000 | ||

| Capacity | Swing over bed | 860 | 960 | |||

| Swing over cross slide | 540 | 640 | ||||

| Swing over gap | 1200 | 1300 | ||||

| Distance between centers | 1000 | 1500 | 2000 | 3000 | ||

| Bed | Width of bed | 510 | ||||

| Length of gap (Spindle end face) |

240 | |||||

| Length of bed | 3300 | 3800 | 4300 | 5300 | ||

| Headstock | Spindle bore | Ø105 (4") | OP:152 (6") | |||

| Spindle nose | A2-8 | A2-11 | ||||

| Number of spindle speeds | 12 | 12 | ||||

| Range of spindle speeds | 23~1300 | 16~810 | ||||

| Carriage | Width of carriage | 660 | ||||

| Cross slide travel | 510 | |||||

| Compound rest travel | 370 | |||||

| Max. size cutting size | 32 x 32 | |||||

| Tailstock | Diameter of barrel | Ø125 | ||||

| Travel of barrel | 300 | |||||

| Taper of barrel | MT# 6 | |||||

| Threads | Lead screw diameter & pitches | Ø45x12 mm | ||||

| Range of metric pitches | 0.8~14 mm (65 Nos) | |||||

| Range of inch pitches | 2~28 T.P.I. (36 Nos) | |||||

| Range of diametral pitches | 4~56 D.P. (36 Nos) | |||||

| Range of module pitches | 0.5~7 M.P. (22 Nos) | |||||

| Feeds | Fed rod diameter | 32 | ||||

| Range of longitudinal feeds | 0.050 ~ 0.70 mm/rev | |||||

| Range of cross feeds | 0.025 ~ 0.35 mm/rev | |||||

| Motor | Main spindle motor | 15 HP | OP: 20 HP | |||

| Coolant pump motor | 1/8 HP | |||||

| Rapid motor | 1/4 HP | |||||

| Machine Size | Machine size (L) | 3600 | 4100 | 4600 | 5600 | |

| Machine size (WxH)- without back splash guard |

W: 1550 x H: 1500 (HT-860) / 1550 (HT-960) / 1630 (HT-1120) / 1680 (HT-1220) | |||||

| The width of machine size with back splash guard: 1800 | ||||||

| Measurement | N.W. / G.W. (approx) Kg | HT-860 | 6900/7000 | 7200/7350 | 7500/7700 | 8100/8400 |

| HT-960 | 7150/7250 | 7450/7600 | 7750/7950 | 8350/8650 | ||

| HT-1120 | 7550/7650 | 7700/7850 | 8000/8200 | 8600/8900 | ||

| HT-1220 | 7800/7900 | 7950/8100 | 8250/8450 | 8850/9150 | ||

| Packing size (L) | 3900 | 4400 | 4900 | 5900 | ||

| Packing size (WxH)- without back splash guard |

W: 1900 x H: 1900 (HT-860) / 1950 (HT-960) / 2030 (HT-1120) / 2080 (HT-1220) | |||||

| The width of machine size with back splash guard: 2100 | ||||||

| Standard Color | RAL-9022 LIGHT GRAY | |||||

- ※ We reserve the right to modify and improve our products without notice.

Unit: mm

| ITEM | HT-1120 | HT-1220 | ||||

|---|---|---|---|---|---|---|

| MODEL | 4000 | 5000 | 6000 | 7000 | ||

| Capacity | Swing over bed | 1120 | 1220 | |||

| Swing over cross slide | 800 | 900 | ||||

| Swing over gap | 1460 | 1560 | ||||

| Distance between centers | 4000 | 5000 | 6000 | 7000 | ||

| Bed | Width of bed | 510 | ||||

| Length of gap (Spindle end face) |

240 | |||||

| Length of bed | 6300 | 7300 | 8300 | 9300 | ||

| Headstock | Spindle bore | OP:152 (6") | OP: 152 (6") | |||

| Spindle nose | A2-11 | A2-11 | ||||

| Number of spindle speeds | 12 | 16 | ||||

| Range of spindle speeds | 16~810 | 4~420 | ||||

| Carriage | Width of carriage | 660 | ||||

| Cross slide travel | 510 | |||||

| Compound rest travel | 370 | |||||

| Max. size cutting size | 32 x 32 | |||||

| Tailstock | Diameter of barrel | Ø125 | ||||

| Travel of barrel | 300 | |||||

| Taper of barrel | MT# 6 | |||||

| Threads | Lead screw diameter & pitches | Ø45x12 mm | ||||

| Range of metric pitches | 0.8~14 mm (65 Nos) | |||||

| Range of inch pitches | 2~28 T.P.I. (36 Nos) | |||||

| Range of diametral pitches | 4~56 D.P. (36 Nos) | |||||

| Range of module pitches | 0.5~7 M.P. (22 Nos) | |||||

| Feeds | Fed rod diameter | 32 | ||||

| Range of longitudinal feeds | 0.050 ~ 0.70 mm/rev | |||||

| Range of cross feeds | 0.025 ~ 0.35 mm/rev | |||||

| Motor | Main spindle motor | OP: 20 HP | OP: 6" 20 HP | |||

| Coolant pump motor | 1/8 HP | |||||

| Rapid motor | 1/4 HP | |||||

| Machine Size | Machine size (L) | 6600 | 7600 | 8600 | 9600 | |

| Machine size (WxH)- without back splash guard |

W: 1550 x H: 1500 (HT-860) / 1550 (HT-960) / 1630 (HT-1120) / 1680 (HT-1220) | |||||

| The width of machine size with back splash guard: 1800 | ||||||

| Measurement | N.W. / G.W. (approx) Kg | HT-860 | 8700/9100 | 9300/9800 | 9900/10500 | 10500/11200 |

| HT-960 | 8950/9350 | 9550/10050 | 10150/10750 | 10750/11450 | ||

| HT-1120 | 9200/9600 | 9800/10300 | 10400/11000 | 11000/11700 | ||

| HT-1220 | 9450/9850 | 10050/10550 | 10650/11250 | 11250/11950 | ||

| Packing size (L) | 6900 | 7900 | 8900 | 9900 | ||

| Packing size (WxH)- without back splash guard |

W: 1900 x H: 1900 (HT-860) / 1950 (HT-960) / 2030 (HT-1120) / 2080 (HT-1220) | |||||

| The width of machine size with back splash guard: 2100 | ||||||

| Standard Color | RAL-9022 LIGHT GRAY | |||||

- ※ We reserve the right to modify and improve our products without notice.