Heavy Duty CNC Lathe

DHT 860, 1120 X 1000, 1500, 2000, 3000, 4000, 5000, 6000

SPINDLE BORE: 4", 6"

BED WIDTH: 20" (510mm)

*Standard accessories shall be subject to the quotation.

- 1. The slide way and ball screw can be lubricated automatically by central lubrication system. Oil flow and lubrication frequency can be set as desired. An alarm occurs in case of lack of oil.

- 2. The coolant system delivers high pressure coolant to flush chips and extend tool service life.

- 3. Mechanical and electrical are designed all in one.

- 4. FC-30 steel are used for main structures like base, spindle, saddle and tailstock, which are annealed and have no deformation.

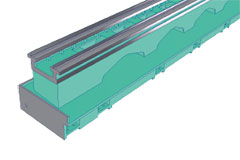

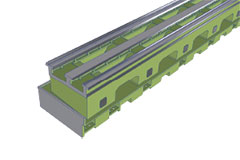

- 5. The structure of bed is adopted high toughness Meehanite cast iron; stabilize properly parallel precision. Bed ways are induction hardened and ground.

- 6. One -piece casting base for processing capacity to be more stable.

- 7. HEADSTOCK -Spindle 4-step speed auto change

- Photo shown headstock with spindle bore 152mm(6").

- The spindle bore diameter 4” or 6 “ are supported by precision heavy duty bearings at three points.

- Equipped with hydraulic cylinder for automatic speed change, with four-speed gears speed change, each speed can be output at full horsepower, and can achieve high-precision and heavy-duty cutting.

- Gear and shaft are made of super alloy material with NSK bearings to offer durable cutting and low production noise.

- Sealed oil bath lubrication system with enforced oil supply by mechanical pump to achieve better lubrication effects.

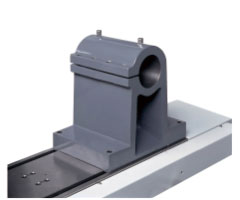

- 8. Tailstock

- Photo shown Option : Tailstock with hydraulic quill.

- Tailstock extended quill match up with H4 turret or V8 hydraulic turret can do cutting of long workpiece.

- Depend on the requirement of client, tailstock quill can be changed to optional hydraulic quill and tailstock base with hydraulic lock bolt.

- Standard with saddle-tailstock device makes the tailstock body move smoothly and the operation is labor saving.

- Optional function of tailstock base moving motorized is available.

- 9. High quality control components

- The control circuit in the electrical cabinet consists of high-quality electronic components, featuring maximum stability of control performance and long service.

- The electrical cabinet is equipped with a heat exchanger to ensure constant temperature.

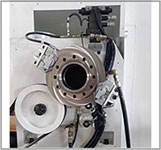

- Photo shown Option : Boring attachment

- Special customized boring attachment and boring bar can be installed on the cross slide, and the diameter and depth of the boring hole can be controlled by programming.

- Special customized bushings can be produced for different processing requirement to install different sizes of boring bars.

- According to customer needs, it can be equipped with a cooling system with coolant through center.

(without chuck and turret)

- 1. Controller: FANUC

- 2. Spindle 4-steps speed auto. Change

- 3. XZ-axes auto. lubrication system

- 4. XZ-axes with Turcite-B

- 5. XZ-axes C3 ball screw

- 6. Rear Chain type Chip conveyor

- 7. Manual Tailstock

- 8. Steady rest 11.5"

- 9. Coolant system

- 10. Full enclosed splash guard

- 11. Spindle oil cooler

- 12. Air conditioner (for electric cabinet)

- 13. Dead center

- 14. Tools & tool box & level pads

- 15. Operational manual

- 1. Chuck:

- 1-1. 3-aw scroll chuck

- 1-2. 4-jaw independent chuck

- 1-3. Face plate with 4-jaw

- 1-4. Hydraulic 3-jaw through-hole power chuck

- 1-5. Hydraulic 3-jaw none through hole power chuck

- 1-6. 3-jaw air chuck

- 2. Turret:

- 2-1. Hydraulic turret H4

- 2-2. Hydraulic turret H4-VDI

- 2-3. Hydraulic turret V8 / VDI disk

- 2-4. Hydraulic turret V12 / VDI disk

- 2-5. Powerful live turret (must match with C-axis)

- 3. Transformer

- 4. Follow rest

- 5. Steady rest ø15", ø20"

- 6. Hydraulic steady rest

- 7. Double turret

- 8. Double chuck

- 9. Linear scale

- 10. C-axis function & spindle hydraulic brake

- 11. Boring attachment

- 12. Tailstock

- 12-1. with self-rotary quill

- 12-2. hydraulic on quill

- 12-3. base motorized

- 12-4. base hydraulic lock bolt

|

|

|

| 1-1. 3-aw scroll chuck | 1-2. 4-jaw independent chuck | 1-4. Hydraulic 3-jaw through-hole power chuck |

|

|

|

| 1-6. 3-jaw air chuck | 5. Steady rest | 2-1. Hydraulic turret H4 |

|

|

|

| 2-2. Hydraulic turret H4-VDI | 2-3,4. Hydraulic turret V8,V12 | 2-5. Powerful live turret |

|

|

|

| 6. Hydraulic steady rest | 7. Double turret | |

|

|

|

| 8. Double chuck | 10. C-axis function & spindle hydraulic brake | |

|

||

| 12-1. Tailstock with self-rotary quill | ||

| SPECIFICATION | Unit: mm | |||||||

| DHT Bed width | 510 | |||||||

| DHT-860-105 | SPINDLE | |||||||

| Swing over bed | 860 | Bore | Ø105 | 4" | ||||

| Center Height | 430 | Nose | A2-11 | |||||

| Swing over cross slide | 500 | Speed | 23~1300 rpm | Motor α15 (15 kw) | ||||

| X-Axis Travel | 430 | ◎The X-axis stroke changes with the turret specifications. | ||||||

| X-axis Ball Screw | C3 Ø25 P5 | Feed : Rapid 5000 / Cutting 3000 mm/min | Motor α12 (3kw) | |||||

| DHT-860-152 | SPINDLE | |||||||

| Swing over bed | 860 | Bore | ø152 | 6" | ||||

| Center Height | 430 | Nose | A2-11 | |||||

| Swing over cross slide | 500 | Speed | 16 - 810 rpm | Motor α18 (18.5 kw) | ||||

| X-Axis Travel | 430 | ◎The X-axis stroke changes with the turret specifications. | ||||||

| X-axis Ball Screw | C3 Ø25 P5 | Feed : Rapid 5000 / Cutting 3000 mm/min | Motor α12 (3kw) | |||||

| DHT-1120-152 | SPINDLE | |||||||

| Swing over bed | 1120 | Bore | ø152 | 6" | ||||

| Center Height | 560 | Nose | A2-11 | |||||

| Swing over cross slide | 760 | Speed | 6 - 500 rpm | Motor α22 ( 22 kw) | ||||

| X-Axis Travel | 560 | ◎The X-axis stroke changes with the turret specifications. | ||||||

| X-axis Ball Screw | C3 Ø25 P5 | Feed : Rapid 5000 / Cutting 3000 mm/min | Motor α12 (3kw) | |||||

| Bed | 1M | 1.5M | 2M | 3M | 4M | 5M | 6M | |

| Distance between centers | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | |

| Length of Bed | 3300 | 3800 | 4300 | 5300 | 6300 | 7300 | 8300 | |

| Z-Axis Travel ( Straight bed ) | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | |

| ◎The Z-axis stroke changes with the specifications of the turret, chuck or tailstock. | ||||||||

| Z-axis Ball Screw 1~4 M | C3 Ø50 P10 | Feed : Rapid 5000 / Cutting 3000 mm/min | Motor α22 (4kw) | |||||

| Z-axis Ball Screw 5~6 M | C3 Ø63 P10 | Feed : Rapid 5000 / Cutting 3000 mm/min | Motor α30 (7kw) | |||||

| Turret | ||||||||

| Manual H4-185 | Tool shank size : OD 25 x 25 / ID Ø40 | Tool shank size : OD 32 x 32 / ID Ø40 | ||||||

| OP HydraulicTurret | H4-250 | V8 | V12 | H4-250VDI | ||||

| OP Power Turret | VDI 30 | VDI 40 | BMT45 | BMT55 | ||||

| Cutting performance | Spiral drill Ø14 / Keyway Ø16 / Thread M10*1.5 / M24*1 | Material: Steel St 60 | ||||||

| Tailstock | ||||||||

| Quill Size | Ø115 | Taper MT6 | ||||||

| Manual Quill Travel | 300 | OP: Motorized / Hydraulic type | ||||||

| Body Movement | By saddle | OP: motorized - by rack | ||||||

| Body Lock Type | Manual | OP: Hydraulic type | ||||||

| Machine Size | 1M | 1.5M | 2M | 3M | 4M | 5M | 6M | |

| Length 1~ 6 M | 5105 | 5605 | 6105 | 7105 | 8105 | 9105 | 10105 | |

| Width 1~ 6 M | 2735 | |||||||

| 1~ 6 M Height 1~ 6 M | 2270 | |||||||

| Measurement | 1M | 1.5M | 2M | 3M | 4M | 5M | 6M | |

| DHT- 860 N.W. Kg (approx) | 9000 | 9400 | 9800 | 10600 | 11400 | 12200 | 13000 | |

| DHT- 860 G.W. Kg (approx) | 9300 | 9750 | 10200 | 11100 | 12000 | 12900 | 13800 | |

| DHT-1120 N.W. Kg (approx) | 9400 | 9800 | 10200 | 11000 | 11800 | 12600 | 13400 | |

| DHT-1120 G.W. Kg (approx) | 9700 | 10150 | 10600 | 11500 | 12400 | 13300 | 14200 | |

| Machine Color | Base: RAL-7024 dark gray | Others: RAL-7035 light gray | ||||||

* We reserve the right to modify and improve our products without notice.